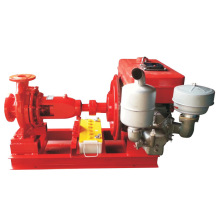

Booster Regulator Water Supply Unit

Basic Info

Model No.: BRWSE

Product Description

Model NO.: BRWSE Structure: Multistage Pump Power: Pneumatic Type: Blade Pump Industry: Mechanical Pump Performance: Fire Pump Water Supply Unit: Water Supply Equipment Fire Fighting Pump: Fire Pump Trademark: Borra Origin: Wenzhou Material: Cast Iron Assembly: Liquid Pumps Start Up: Diesel Engine Application: Clarified Water Pump Media: Sewage Pumps Theory: Jet Pump Fire Pump: Water Pump Pumpset: Water Pumpset Specification: ISO HS Code: 8413810090 Booster Regulator Water Supply Equipment

Booster Regulator Water Supply Equipment is booster regulate equipment,which manufactured based on National Building Standard 98s205 design.The device consist of diaphragm pressure tank, Booster Pump, electric control box, instrumentation and piping accessories and other components, suitable for multi-story and high-rise building and booster requirements for fire hydrant water supply systems and automatic water spraying fire-extinguishing systems and other fire-fighting and Water Supply System.

Features:

1, With pump,electric Control Cabinet, diaphragm type pressure tanks,pipes, four-in-one combination network, and accompanied with the isolator without pre-embedded holes, designers can easily select device model and size,by counting Parameters. Electric Designers do not need to design the control circuit, only need to design for the cable line to pumping stations and the device. Choose convenience, can greatly shorten the design cycle for designers and construction time for builder.

2, Diaphram pressure tank disposable inflatable, durable lifetime. Water vapor isolation can prevent pollution of water.

3, Small occupation area, low investment, automatic operation.

4, Equipment with dual power connector, dual power automatic (manual) switch, the device can be made according to the design requirements.

5, with automatic protection and failover capabilities. Any failure of a pump (electrical failure or hydraulic failure) can start the standby pump.

6, can be connected with the fire center (according to design).

7, can choose the tank, regulator manner based on customer needs and control functions.

8, the main electrical accessories using domestic or brand-name products, reliable and stable operation.

Working Principle

The device has a toxic capsule as air and water isolation system, once inflated can run a year. Start up pump at work, water room fill with water, water pressure increase, chamber air compressed,diaphragm elongationed.When the pressure drops, the air chamber'air expansion,diaphragm contract, pressure water chamber drainage water.This cycle running, control pump operation by electriacal contacts and electrical control box,keep rated power pressure and continuous water supply.when the fire broke out, open the fire hydrant,fire water immediately ejected, meanwhile electrical contacts send a signal to start the fire pump is required for fire-fighting water.

equipment construction

regulator pump two set (depending on design requirements can be one set ),a main pump,a standby pump, a diaphragm pressure tank, a electric cabinet, a combination of instrumentation valves and a pipe network set, consisting of a diaphragm stabilization pressure water supply equipment.

Parameters

Contact us if you need more details on Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Pump、Fire Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Booster Regulator Water Supply Equipment is booster regulate equipment,which manufactured based on National Building Standard 98s205 design.The device consist of diaphragm pressure tank, Booster Pump, electric control box, instrumentation and piping accessories and other components, suitable for multi-story and high-rise building and booster requirements for fire hydrant water supply systems and automatic water spraying fire-extinguishing systems and other fire-fighting and Water Supply System.

Features:

1, With pump,electric Control Cabinet, diaphragm type pressure tanks,pipes, four-in-one combination network, and accompanied with the isolator without pre-embedded holes, designers can easily select device model and size,by counting Parameters. Electric Designers do not need to design the control circuit, only need to design for the cable line to pumping stations and the device. Choose convenience, can greatly shorten the design cycle for designers and construction time for builder.

2, Diaphram pressure tank disposable inflatable, durable lifetime. Water vapor isolation can prevent pollution of water.

3, Small occupation area, low investment, automatic operation.

4, Equipment with dual power connector, dual power automatic (manual) switch, the device can be made according to the design requirements.

5, with automatic protection and failover capabilities. Any failure of a pump (electrical failure or hydraulic failure) can start the standby pump.

6, can be connected with the fire center (according to design).

7, can choose the tank, regulator manner based on customer needs and control functions.

8, the main electrical accessories using domestic or brand-name products, reliable and stable operation.

Working Principle

The device has a toxic capsule as air and water isolation system, once inflated can run a year. Start up pump at work, water room fill with water, water pressure increase, chamber air compressed,diaphragm elongationed.When the pressure drops, the air chamber'air expansion,diaphragm contract, pressure water chamber drainage water.This cycle running, control pump operation by electriacal contacts and electrical control box,keep rated power pressure and continuous water supply.when the fire broke out, open the fire hydrant,fire water immediately ejected, meanwhile electrical contacts send a signal to start the fire pump is required for fire-fighting water.

equipment construction

regulator pump two set (depending on design requirements can be one set ),a main pump,a standby pump, a diaphragm pressure tank, a electric cabinet, a combination of instrumentation valves and a pipe network set, consisting of a diaphragm stabilization pressure water supply equipment.

Parameters

| NO. | Booster Regulator Device Model | Fire Pressure(Mpa)P1 | Vertical Diaphragm PressureTank Pressure | Working Pressure(Mpa) | Regulators Water Volume (L) | ||||

| Model specification | Working Pressure Ratio αb | Fire Storage Volume(L) | |||||||

| Calibration Volume | Actual Volume | ||||||||

| 1 | ZW(L)-1-X-7 | 0.10 | XQG800×0.6 | 0.60 | 300 | 319 | P1=0.10 PS1=0.26 P1=0.23 PS2=0.31 | 54 | |

| 2 | ZW(L)-1-Z-10 | 0.16 | XQG800×0.6 | 0.80 | 150 | 159 | P1=0.16 PS1=0.26 P1=0.23 PS2=0.36 | 70 | |

| 3 | ZW(L)-1-X-10 | 0.16 | XQG800×0.6 | 0.60 | 300 | 319 | P1=0.16 PS1=0.36 P1=0.33 PS2=0.42 | 52 | |

| 4 | ZW(L)-1-X-13 | 0.22 | XQG1000×0.6 | 0.76 | 300 | 329 | P1=0.22 PS1=0.35 P1=0.32 PS2=0.40 | 97 | |

| 5 | ZW(L)-1-XZ-10 | 0.16 | XQG1000×0.6 | 0.65 | 450 | 480 | P1=0.16 PS1=0.33 P1=0.30 PS2=0.38 | 86 | |

| 6 | ZW(L)-I-XZ-13 | 0.22 | XQG1000×0.6 | 0.67 | 450 | 452 | P1=0.22 PS1=0.41 P1=0.38 PS2=0.46 | 80 | |

| 7 | ZW(L)-II-Z- | A | 0.22 -0.38 | XQG800×0.6 | 0.80 | 150 | 159 | P1=0.38 PS1=0.53 P1=0.50 PS2=0.60 | 61 |

| 8 | B | 0.38 -0.50 | XQG800×1.0 | 0.80 | 150 | 159 | P1=0.50 PS1=0.68 P1=0.65 PS2=0.75 | 51 | |

| 9 | C | 0.50 -0.65 | XQG1000×1.0 | 0.85 | 150 | 206 | P1=0.65 PS1=0.81 P1=0.78 PS2=0.86 | 59 | |

| 10 | D | 0.65 -0.85 | XQG1000×1.6 | 0.85 | 150 | 206 | P1=0.85 PS1=1.04 P1=1.02 PS2=1.10 | 57 | |

| 11 | E | 0.85 -1.0 | XQG1000×1.6 | 0.85 | 150 | 206 | P1=1.00 PS1=1.21 P1=1.19 PS2=1.27 | 50 | |

| 12 | ZW(L)-II-X- | A | 0.22-0.38 | XQG800×0.6 | 0.78 | 300 | 302 | P1=0.38 PS1=0.53 P1=0.50 PS2=0.60 | 72 |

| 13 | B | 0.38-0.50 | XQG800×1.0 | 0.78 | 300 | 302 | P1=0.50 PS1=0.68 P1=0.65 PS2=0.75 | 61 | |

| 14 | C | 0.50-0.65 | XQG1000×1.0 | 0.78 | 300 | 302 | P1=0.65 PS1=0.88 P1=0.86 PS2=0.93 | 51 | |

| 15 | D | 0.65-0.85 | XQG1200×1.6 | 0.85 | 300 | 355 | P1=0.85 PS1=1.05 P1=1.02 PS2=1.10 | 82 | |

| 16 | E | 0.85-1.0 | XQG1200×1.6 | 0.85 | 300 | 355 | P1=1.00 PS1=1.21 P1=1.19 PS2=1.26 | 73 | |

| 17 | ZW(L)-II-XZ- | A | 0.22-0.38 | XQG1200×0.6 | 0.80 | 450 | 474 | P1=0.38 PS1=0.53 P1=0.50 PS2=0.60 | 133 |

| 18 | B | 0.38-0.50 | XQG1200×1.0 | 0.80 | 450 | 474 | P1=0.50 PS1=0.68 P1=0.65 PS2=0.75 | 110 | |

| 19 | C | 0.50-0.65 | XQG1200×1.0 | 0.80 | 450 | 474 | P1=0.65 PS1=0.81 P1=0.78 PS2=0.86 | 90 | |

| 20 | D | 0.65-0.85 | XQG1200×1.6 | 0.80 | 450 | 474 | P1=0.85 PS1=1.04 P1=1.02 PS2=1.10 | 73 | |

| 21 | E | 0.85-1.0 | XQG1200×1.6 | 0.80 | 450 | 474 | P1=1.00 PS1=1.21 P1=1.19 PS2=1.27 | 64 | |

Contact us if you need more details on Pump. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Water Pump、Fire Pump. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Fire Pump

Premium Related Products

Other Products

Hot Products

Lw Series Vertical Centrifugal Sewage Water PumpVerical Mining Pipeline Centrifugal Water PumpNon Clogging Marine Sewage Water PumpDisel Engine Double Suction Split Casing Irrigation Water PumpWater Supply Equipment with No Negative PressureDiesel Fire Pump for Vehicle Five TruckSewage Pump Whth Qw Not Easy to Wear and Clogging PipesHorizontal Self-Priming Chemical Centrifugal PumpHigh Efficiency Heavy Flow Vertical Axial Flow Irrigation Water PumpStainless Steel Horizontal Multistage Centrifugal Water PumpNon Negative Pressure Variable Frequency Constant Pressure Water Supply EquipmentHigh Efficiency Double Suction Split Casing Centrifugal Water PumpHorizontal Cantilever stainless Steel Chemical Proces Centrifugal Water PumpHigh Efficiency Vertical Pipeline Booster Centrifugal Water PumpHigh Efficiency Non-Clogging Submersible Sewage Centrifugal Irrigation Water PumpCentrifugal Water Pump for Water and Chemical Liquid